Impact attenuator

The idea:

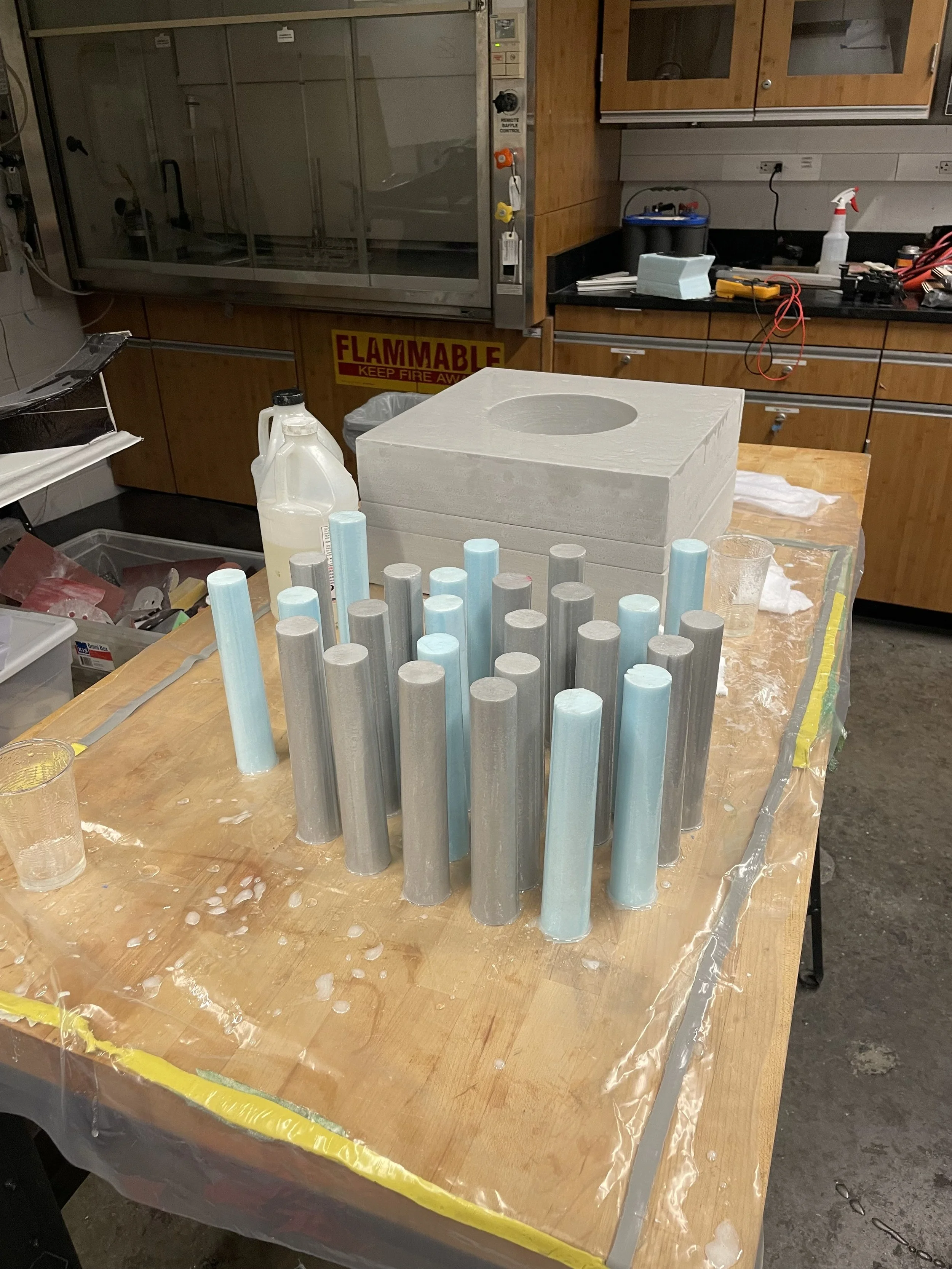

This project came from The Cooper Union Summer Race Car Research Program, where I worked with their FSAE team to develop a composite impact attenuator to replace their heavier aluminum baseline. The goal was to design a structure that could absorb the required energy in a frontal impact while reducing weight. The main constraints were meeting FSAE energy-absorption requirements and being manufacturable with the composite fabrication tools we had available.

The process:

I went through one full design-build-test cycle during the program:

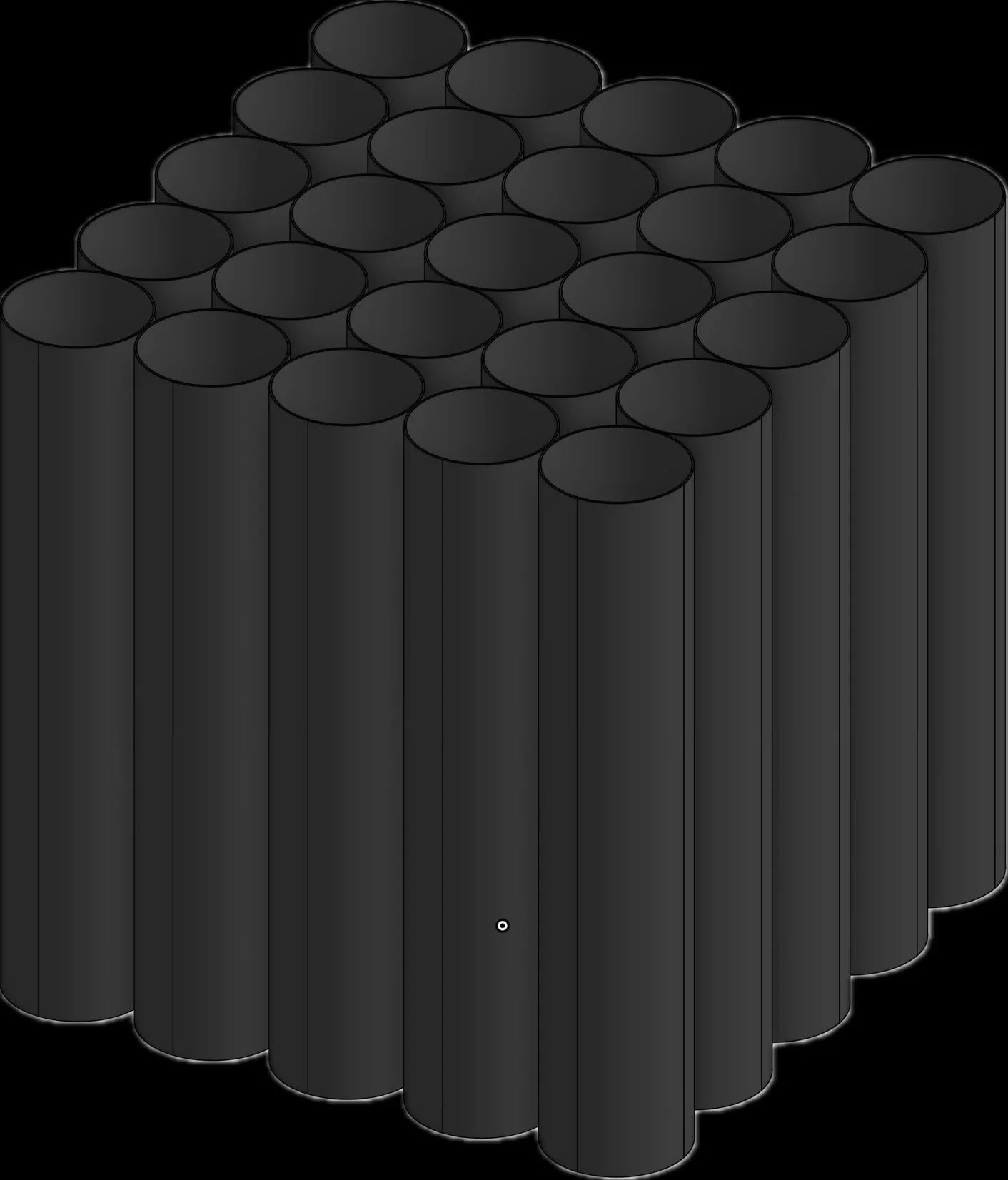

First, I created CAD geometry for the attenuator and used calculations to predict how the structure would behave under crush loading. From there, I CNC-milled the molds and fabricated carbon fiber layups by hand. Once the parts were cured, I ran crush-rig tests to measure how much energy the structure actually absorbed and compared the results to my calculations.

The first design didn't meet the FSAE requirements, so I began a second iteration, adjusting the geometry and layup schedule based on what I learned from the test data. The program ended before I could fabricate and test the revised design.

The result:

While the project didn't reach a final, validated design, I came away with hands-on experience in the full composite fabrication process, from mold-making to layup to crush testing. More importantly, I learned how to use real test data to inform the next iteration, closing the gap between what a design is supposed to do on paper and what it actually does when you break it.